Timiak Tech

Visual acuity measurement through virtual reality and artificial intelligence

It is believed that roughly 35% of the population would need to wear glasses. In order to gauge visual acuity, Opticians use a special device called phoropter that enables accurate measurement by testing different types of lenses and other correcting adjustments.

Thanks to the phoropter, along with the subject’s feedback, the Optician can prescribe the right solution.

The subjective nature of this feedback (the person gauging how suitable the lenses may be) is one of the phoropter’s main shortcomings, since it becomes hard to use accurately with part of the population (small children, people with disabilities, etc..).

TIMIAK TECH is at an advanced stage of development of the first Smart VR Phoropter, a device using the same working principles as a traditional phoropter, adding the power of electronics, virtual reality and artificial intelligence to shift the vision correction paradigm, based now on smart eye behaviour analysis rather than subjective judgement.

Timiak Tech doesn’t only improve on the limitations of the traditional method, but delivers a prescription in a faster, more accurate, reliable fashion.

The starting point

Timiak Tech was accurately briefed on technical requirements and scoped the project down to detail, which was very demanding in terms of technical complexity.

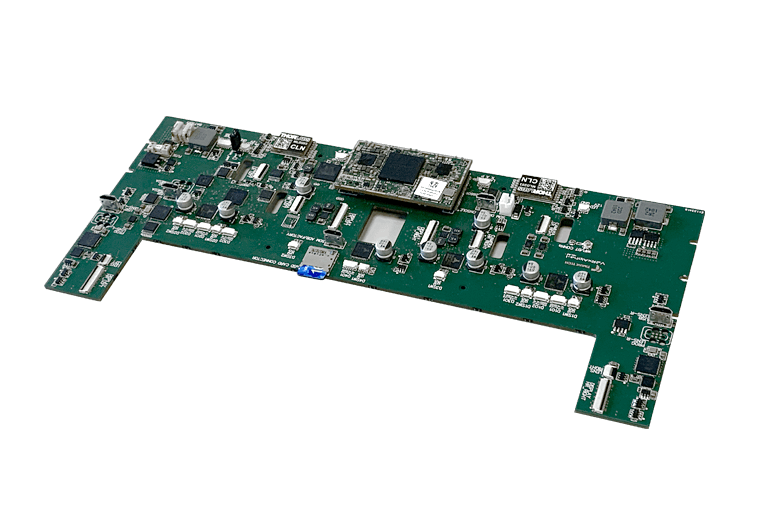

This involved the design and build of a motherboard that should be able to simultaneously handle:

- Multiple high-resolution displays.

- Multiple high definition cameras.

- Data gathering of all sensors in the device.

- Real-time support of all accessories and moving parts of the product.

It all required a high degree of mechanical integration (given its context of use) on a very tight budget and timeline, in order to validate the Alpha phase of development.

The solution

This project clearly exemplifies the close correlation between the commercial viability of a product and its accurate feasibility study.

NITSNETS Devices adopted a strategy of ongoing idea validation, so as to use evidence-based resource allocation during development.

We started by selecting the right components and technology, keeping unit costs within budget. At analysis and concept level, decisions were made to minimise efforts and technical debt in firmware development. This was followed by the design of the circuit diagram and its layout, using a modular strategy to enable better mechanical integration.

The project was delivered on time, notwithstanding the risk involved in such a technically complex endeavour. Throughout the whole development we strove to both optimise manufacturing and reduce development and components cost significantly.

A high degree of innovation to turn a disruptive idea into a revolutionary optometry product